Details

Product Description

Swing-Arm Robots are extensively applied to horizontal / vertical plastic injection machines ranging from 50T~ 250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 650mm, 750mm and for telescopic is 850mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Product Specification / Models

Structural Units:

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Employed high strength & tension aluminum alloy to work with precise linear guide way, features with light weight, wear resistance, long service life.

Wrist Rotation Mechanism:

The arm front section for installing gripper can rotate 90°; absorbs & gripper jig can be installed with sensor device for detecting to get products or not.

Application / Models

Swing-Arm Robots are extensively applied to horizontal / vertical plastic injection machines ranging from 50T~ 250T which can rapid take out the runners, runner and finished products from the mold of plastic injection molding machines, and place runners or runner into beside-the-press granulator for recycling immediately. There are two types of arms-single stage and telescopic. The vertical stroke for single stage is 550mm and for telescopic is 650mm. This series equipped with wrist rotation mechanism and gripper sensor can rotate products with 90°.

Main Specification

| Model | Power Capacity(KVA) | Recommended I.M.M(Ton) | Main Vertical Stroke(mm) | Sub Vertical Stroke(mm) | Crosswise Stroke(mm) | Swing angle(KVA) | Dry Take Out Time(sec) | Max.loading(kg) | Dry Cycle Time(sec) | Air Consumption(NI/cycle) | Net Weight(kg) |

| mySWING-650D | 0.2 | 50-150 | 650 | 650 | 120 | 60-90 | 1.2 | 2 | 4.4-4.2 | 13 | 52 |

| mySWING-650S | 50-150 | 650 | - | 120 | 60-90 | 0.9 | 2 | 4.8 | 13-Dec | 36-48 | |

| mySWING-750D | 150-200 | 750 | 750 | 200 | 1.2 | 4.2-4 | 13 | 49 | |||

| mySWING-750S | 150-200 | 750 | - | 1.0 | 4.2-4 | 13 | 49 | ||||

| mySWING-850TS | 200-280 | 850 | - | 1.1 | 5.2 | 14.5 | 55 | ||||

| mySWING-850D | 200-280 | 850 | 850 | 1.4 | 6 | 15.5 | 53 |

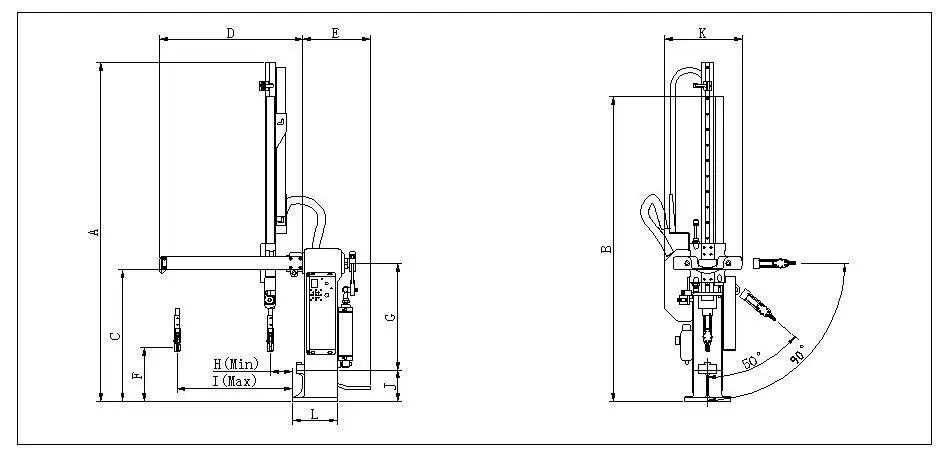

Outer Dimension

Control System

- Convenient and easy for customers to use with 8-20standard program sequences and 80 freely programmable teach programs for flexible applications.

- A unique menu interface, which indicates all the functions for the user on screen for convenient program selection.

- Multi- language support using a simple screen selection button for English and Chinese.

- Polished and firm design for the control shell made of PC+ABS materials, resist high temperature.

View more about mySWING-650S. Single Arm on main site